The entire design of the Vertical Pit Pump revolves around reducing resistance and improving flow.

PUMPS 7,000 GPM

Loads and agitates faster than the competition. Available in 8', 9', 10', 11', 12', 13', 14', 15', 16' fixed models and 8'-12', 9'-14', 10'-16', 12'-18' variable length models.

TRIPLE PORT OUTLET

The liquid leaves the housing in three spots, this reduces the amount of input power, while increasing performance.

OPTIONAL RADIO CONTROL

This allows for wireless control of the valve to switch from "agitate" to "fill" and wireless control of agitator movements. 300ft range.HEADER SERIES CONCEPT

The Header Series Concept with White Iron Housing provides ultimate protection in sand environments.FEATURES

Nuhn Pumps, load and agitate faster than the competition.

2PT, 3PT & trailer models available. Optional multi depth & dual agitators.

Nuhn Industries pumps more while using 1/2 the fuel.

With multiple outlets, the manure is able to get out of the housing faster which will pump greater volumes of manure while using less horsepower.

THE HEADER SERIES DIFFERENCE

MASSIVE AGITATION CAPACITY

FINISH SOONER

HIGH EFFICIENCY DESIGN

Strongest Sealing Solution in the Industry

The MECH-TC sealing system, exclusive to the Nuhn Header Series, utilizes a tungsten carbide mechanical seal to effectively protect the drive line and bearings. Tungsten carbide is extremely hard and wear resistant, which results in extended seal life in the harshest environments. The sealing system has been designed to withstand sand and other abrasive compounds. The MECH-TC system is designed to withstand tremendous load with three bearings, 2 tapered bearings and one needle bearing. The system is encased in an oil bath for ease of maintenance.

8" Vertical Pit Pump |

17" Housing Pumps, this is smaller than the standard Nuhn Pumps.

8" Vertical Pit Pump|

Row of Vertical Pit Pumps

8" Vertical Pit Pump |

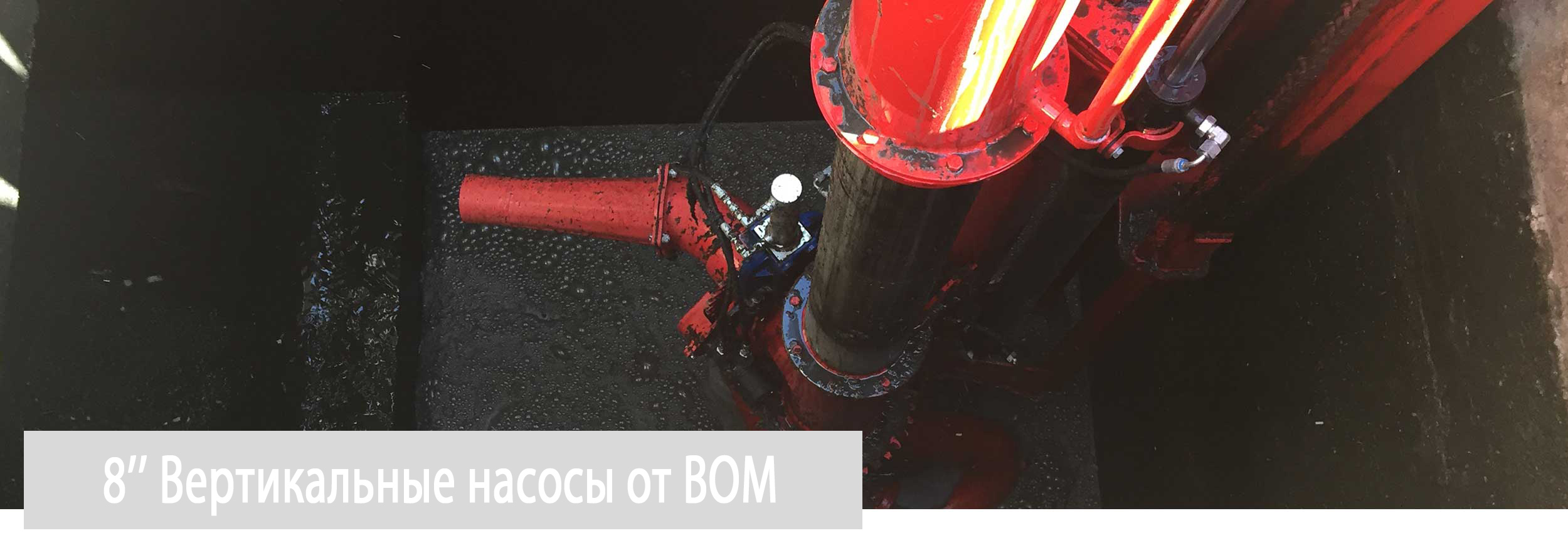

Pit Pump in a manure pit

8" Vertical Pit Pump |

Pit Pump In a Manure Pit

8" Vertical Pit Pump |

Nuhn White Cast Iron Housing

8" Vertical Pit Pump |

Agitator Nozzle in action and a manure pit.

8" Vertical Pit Pump |

17" Housing Pumps, this is smaller than the standard Nuhn Pumps.

TECHNICAL SPECIFICATIONS

Drive Line

- 1 3/4″ shaft with 3.25″OD hardened steel drive shaft sections

- 10′ sections of connected with heavy duty 80 series universal joint

- Completely enclosed drive assembly with G-Force seal and bearing unit on both ends

- Large clean-out doors for easy access to bearings

Agitator

- 4″ nozzle to create 45psi of pressure with 4000GPM volume

- End nozzle rotates 360°

- Main rotation pipe is able to rotate 300°

| Maximum Flow | Maximum RPM | Minimum HP Required | Maximum HP Required | Pipe Size | Agitator Rotation | Agitator Height Rotation | Agitator Outlet Diameter | Overall Housing Width | Drive Shaft Diameter |

|---|---|---|---|---|---|---|---|---|---|

| 7000 GPM | 1000 RPM | 95 HP | 180 HP | 8" ID | 320° | 360° | 5" | 32" | 4" OD |

| Drive Shaft Yoke Size | Sealing System | Lubrication Style | Hydraulic Control | Main Frame | Wear Materials | Impeller Diameter | Impeller Style | Wireless Control |

|---|---|---|---|---|---|---|---|---|

| 55/80 Series | Mechanical | Oil Bath | Standard | 8" x 8" x 1/4" | White Iron | 20.5"360° | 4 Blade | Optional |